WASTE NOT. WANT NOT.

Often attributed to a writing by Benjamin Franklin shortly before the signing of the Declaration of Independence, these few words are particularly germane when thinking about water as drought conditions grip the US Southwest.

While catching up on reading March and April issues of Water Conditioning & Purification Magazine, I was intrigued by back-to-back articles about the reclamation of spent brine from the regeneration of water softeners. The authors were educated, experienced, and well-respected professionals in the water conditioning industry. One offered a process that would be relatively inexpensive to accomplish and looked to permit about 10% reuse. The other proposed process involves the addition of rather expensive components, but a net reclamation estimated at 40%.

As part of the April presentation, the following numbers were expressed:

- 10,000,000 residential water softeners in the US

- 60,000 commercial water softeners in the US

These units not only consume salt, but of equal if not more importance they discharge (waste water) to drain during regeneration in huge accumulated volumes. Based on the stated unit volumes, the wasted water is:

- Residential(1) 31.2 BILLION GALLONS ANNUALLY

- Commercial(2) 3.37 BILLION GALLONS ANNUALLY

Notes:

- 40 gallons per regeneration. 1-1/2 regenerations weekly.

- 360 gallons per regeneration. 3 regenerations weekly. 24” DIA. Media tank.

Admittedly, there is a small percentage of applications where there is a need to remove calcium and or magnesium from water and replace it with sodium from salt, but in the vast majority of applications, preventing hardness scale and soap scum is of primary concern. This can be accomplished with a number of time-tested technologies that waste zero water. These technologies include magnetic, catalytic and a combination of the two.

Beware of salt-based softeners advertised as being “efficient” or high efficiency” As salt consumption per regeneration is reduced, there is a corresponding reduction in system capacity. This means that such systems need to regenerate more frequently and as a result cause excess water wasted to drain.

DIME WATER, INC. has worked for decades to bring to market an extensive list of residential, commercial, and industrial products that have zero water to drain. Additionally, these systems use no chemicals or electricity. Specific models include our ESF, ESF PLUS, AQUAFER, AQUAFER PLUS, and CARTRIDGE FILTERS. Aquafer provides treated water for less than $1 a day.

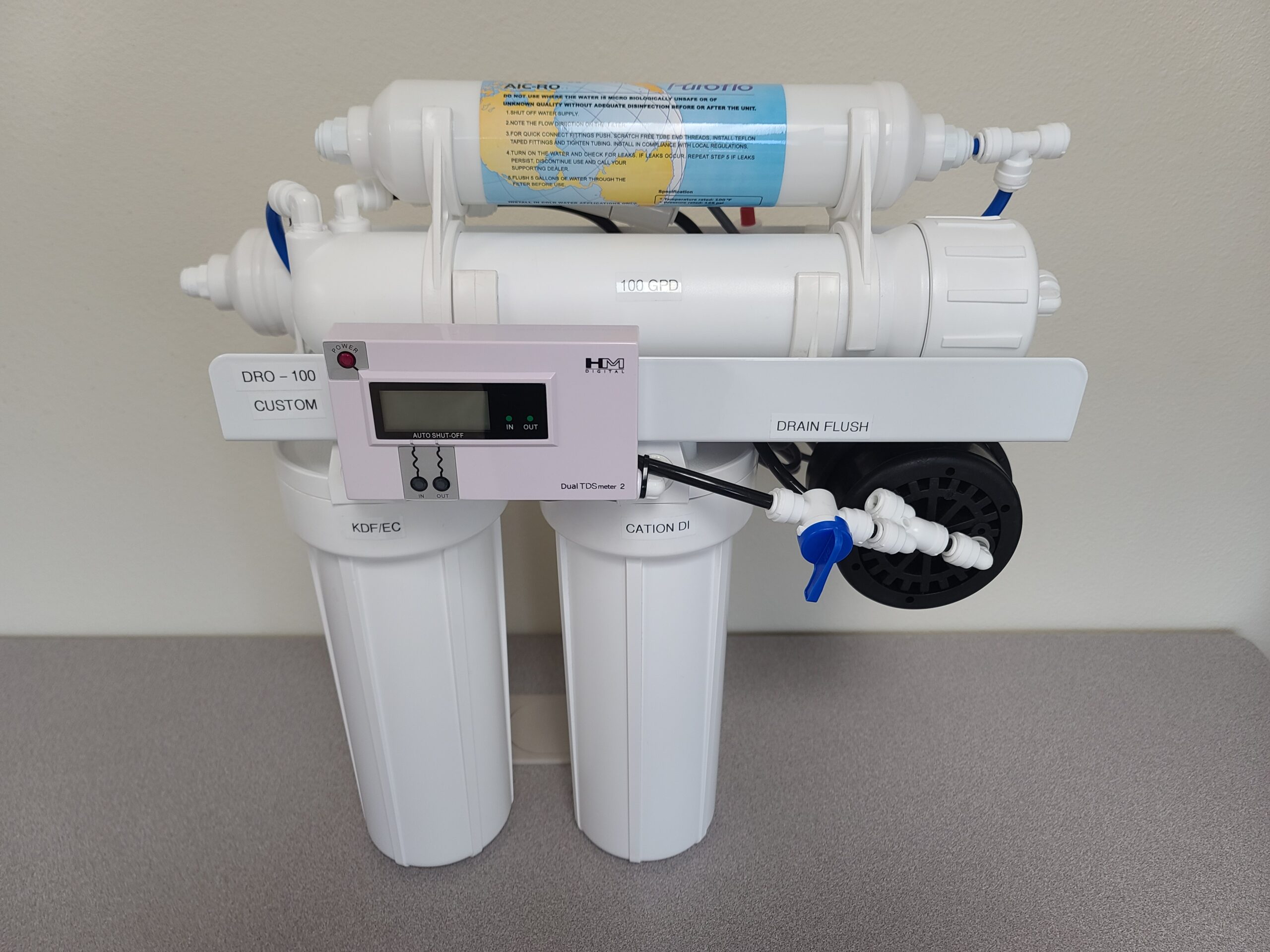

DIME WATER, INC. is in the final development stages of a home under counter reverse osmosis system that is 100% water efficient and has zero water to drain. This compares to competitors’ systems that waste 4 gallons of water for each treated gallon upon start up but easily go to 8 gallons or more to waste for each treated gallon as the tank fills and its back pressure rises. The net result is waste up and quality down.